How to Recycle Plastic as a Manufacturing Company?

When it comes to the recycling of plastics, most people think of post-consumer plastics, i.e. typical household plastic waste. As less than 10 percent of plastics that have been produced to date have been recycled, this is an area where the plastics industry has some catching up to do. Recycling awareness has only become apparent in recent years.

The situation is different with the recycling of production waste, where the edge trim and scrap material have always been reused. After all, around 80 percent of manufacturing costs are for materials. However, many companies are still not sure about how to recycle plastics.

How to Recycle Plastic as a Manufacturing Company: Your Opportunities with PURE LOOP

specially at times of scarcity of raw materials and the subsequent rise in raw material prices , a resource-conserving strategy is becoming increasingly important. This is where recycling technologies come in.

Basically, there are two types of technologies when recycling production waste – inline and offline technologies. The ISEC evo recycling technology can be individually customized for the respective waste management system - both inline and offline.

PURE LOOP Inline and Offline Solution

The inline recycling solution provides a direct connection between the production and the ISEC evo recycling plant, for example via an edge trim receiver for the recycling of edge trimming. Production waste is then continuously processed without intermediate storage or additional handling of material being required.

The offline solution involves the ISEC evo recycling machine being decoupled from the direct production process. The standard designs of the conveyor belt and reel feeder are individually adapted to the customer's requirements. By extending the conveyor belt, it is possible to deposit the production scrap collected in crates, cages or octabins directly onto the conveyor belt using a forklift. The low handling requirements allow for the plant to be supplied with material while saving on personnel and logistics.

Thanks to the high flexibility of the ISEC evo system, it is possible to process different types of plastics as well as different material shapes.

This is How Manufacturing Companies Recycle Plastic Production Waste: A Use Case Example

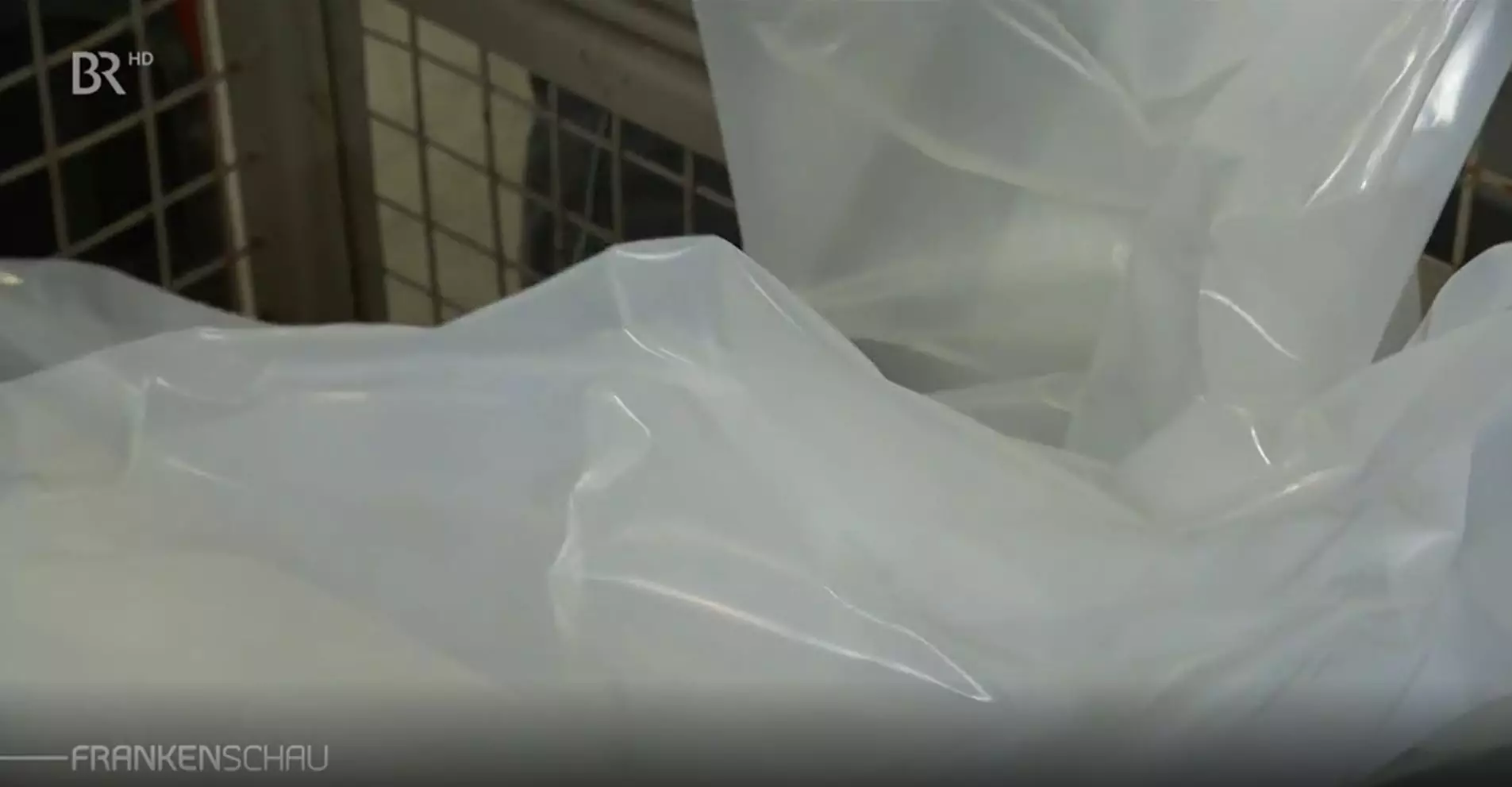

Verpa, a German manufacturer of thickness-reduced PE films, relies on this specific offline recycling solution from PURE LOOP. The use of recycled materials in production plays an important role at Verpa in two ways:

- On the one hand, the waste produced is reprocessed using ISEC evo technology and then returned to production.

- On the other hand, Verpa has set up its own collection system together with its customers. Verpa takes back their bales of scrap film and recycles them. Depending on the customer’s specifications, they are then reused in the production of film.

How to Recycle Plastic - The Summary

How to recycle plastics is a question that many companies are asking themselves. The reason for this is often the high cost of production and materials.

Recycling of plastic production waste is one way to reduce costs. The recycled material in form of pellets can be reused in production thanks to their high quality. This means there is no quality loss in production.

Do you have any further questions about recycling plastics?

Contact us now