Everything To Do With Costs and Amortization When Buying a Recycling Machine

The following factors play an important role in choosing the right recycling machine: the material to be recycled, the recycling technology, integration into existing production processes and, of course, the costs involved. The first three factors were discussed in detail in our blog article Buying a Recycling Machine.

In this blog article, we cover the following questions:

- When does it make sense to buy a recycling machine?

- What is the investment calculation process for an ISEC evo recycling machine?

- At what point will the investment be amortized?

When Does it Make Sense to Buy a Recycling Machine?

TThere are many financial and ecological reasons for investing in a suitable recycling machine for your company. You should certainly think about buying one if you regularly accumulate at least 1.5 tons of plastic production waste per day. In this case, a recycling machine like our ISEC evo will reduce your costs for

- the disposal of production waste,

- processing by an external recycling company and

- the purchase of new material.

By recycling, you can produce high-quality recycled pellets yourself. You can either sell them or feed them back into your production process.

Another reason for many PURE LOOP customers is that they do not want to be entirely dependent on the fluctuating costs of new material. In this case, part of the business model involves purchasing used plastic, recycling it inhouse, and then using the recyclate to manufacture new products.

To make the costs and amortization of a recycling machine transparent, PURE LOOP provides you with an investment calculator. We use this tool with the potential customer to make a reliable purchase decision.

What is the Investment Calculation Process for an ISEC evo Recycling Machine?

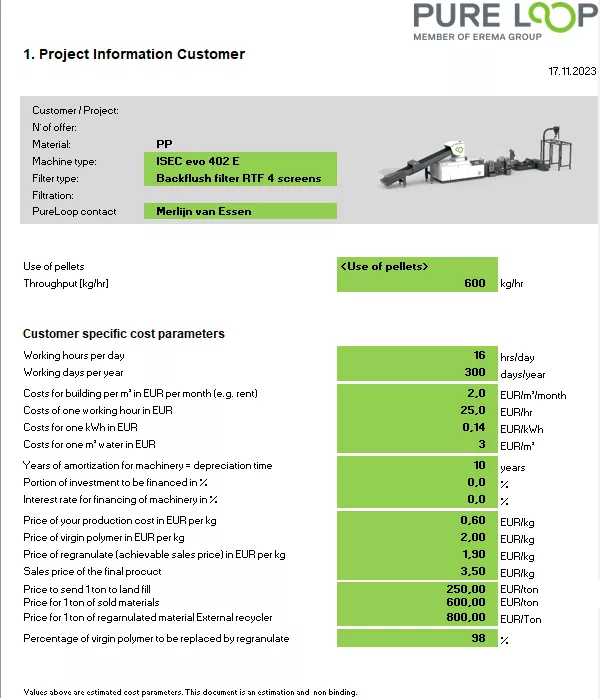

One of the decisive factors for a purchase decision is whether and when an investment in a recycling machine is amortized. That is why PURE LOOP provides potential buyers with the following service: PURE LOOP calculates when the recycling machine will have paid for itself based on detailed information provided by the potential buyer.

To do this, specific information about your company and the production process is needed. This includes:

- Operating hours per day

- Operating days per year

- Cost of the building per m² in EUR/$ per month (e.g. rental)

- Cost of one operating hour in EUR/$

- Cost of one kWh in EUR/$

- Cost of one m³ of water in EUR/$

- Interest rate for financing the machine in %

- etc. (see calculation example based on sample data)

Based on these figures, the investment calculator can be used to calculate the total recycling costs in EUR/kg and $/lb. It also calculates the costs of the recycled pellets produced and the total operating costs of the recycling machine per year. These facts and figures provide the potential buyer with a transparent basis for a purchase decision.

At What Point Will the Investment be Amortized?

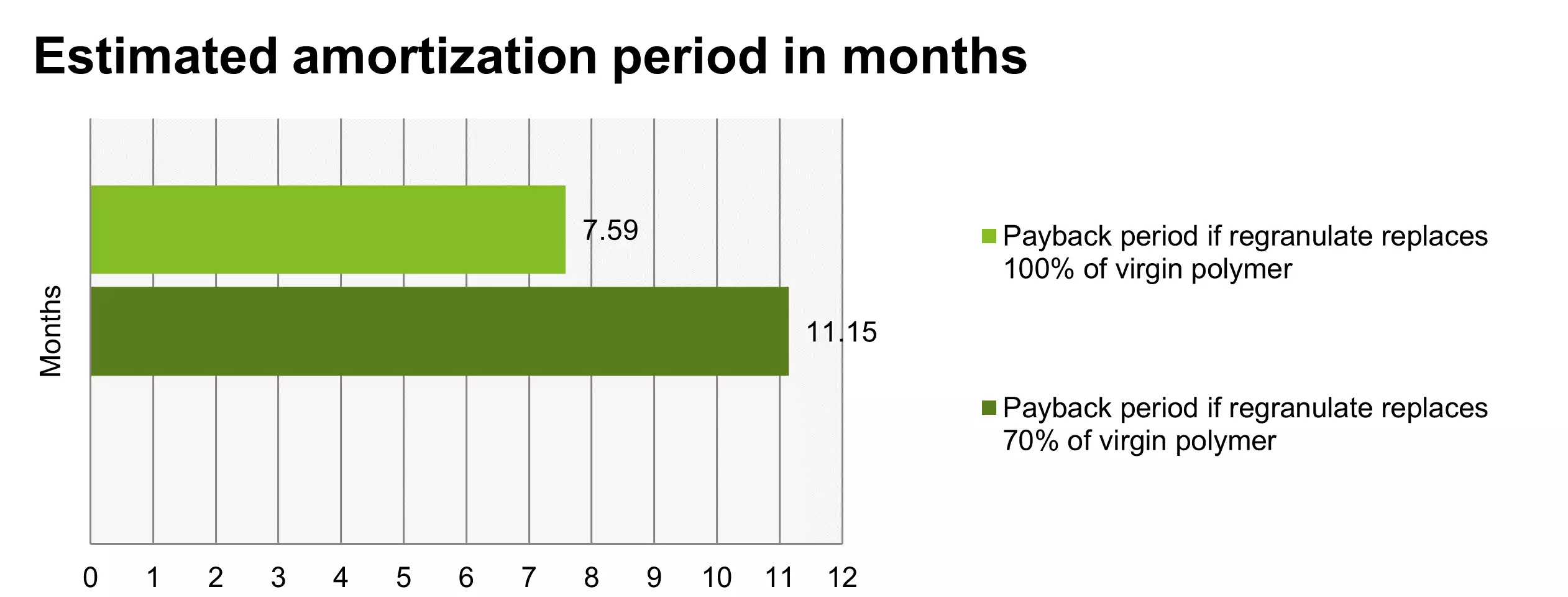

The rate of amortization of the machine quickly changes depending on the operating and production costs and the current market prices for virgin material. The PURE LOOP calculation model gives insight into various scenarios depending on the proportion of recycled pellets that can be fed back into manufacturing new products.

Summary

Before making an investment, it is especially important to analyze all the costs. You can then use the PURE LOOP investment calculator to help you in deciding which type of recycling machine is a profitable investment in your case.

Are you interested in an ISEC evo from PURE LOOP? Contact us now.